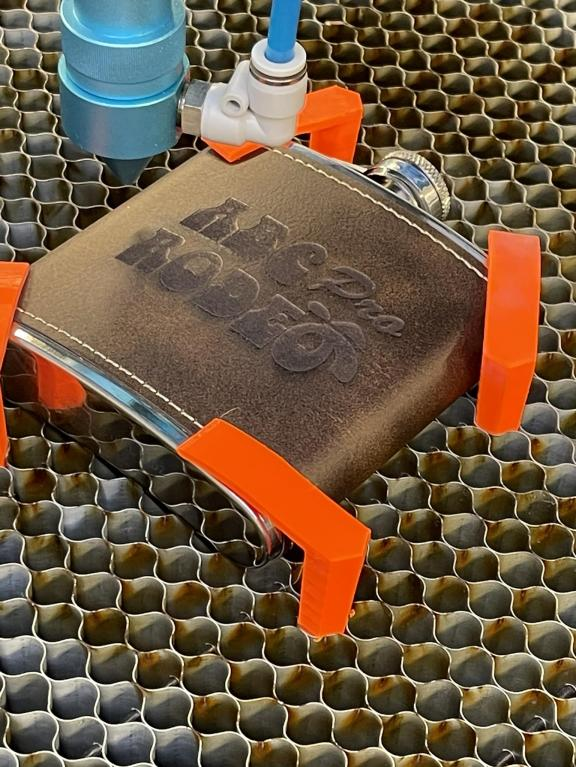

The use of laser engravers in the leather industry has overcome the problems of slow speed, difficult setup, low efficiency, and significant material waste associated with conventional manual and electric shears. The characteristics of fast speed and easy operation have brought great advantages to the development of the leather industry. The laser engraver only needs to input the graphics and sizes to be cut into the computer, and the laser engraver cuts the entire material into the finished product you need according to the data on your computer. No tools or molds are needed, saving a lot of time and effort.

The laser engravers are suitable for engraving materials such as artificial leather, PU leather, PVC artificial leather, genuine leather wool, semi-finished products, various leather fabrics, etc.

There are many types of leather materials, and they are natural materials. Each material reacts differently to laser processing, so there is no standard processing procedure.

If the leather material is deformed during laser processing, the laser processing power must be reduced. Deformation occurs because the laser power is too high and the material surface is heated too much.

Genuine leather, artificial leather, and synthetic leather can all be marked with a laser engraver. However, synthetic leather typically contains PVC components. These materials are best not processed with a laser as PVC materials emit toxic gases when exposed to laser light.

Depending on the laser power used, you can cut leather with a thickness ranging from 1/16 inch to 1/4 inch, and perhaps slightly thicker if you make two passes.

Advantages of laser cutting leather

Using a laser to cut leather has many advantages. Firstly, the laser is able to seal the cut without causing burrs or other wear on the cut. Cutting leather with a laser is fast, precise, and, most importantly, consistent compared to manual leather cutting tools such as utility knives and rotary cutters. Additionally, cutting with a laser eliminates the warping that is sometimes caused by hand tools.

When laser cutting leather, there is no part-to-part contact, meaning no replacement blades or other expensive parts are required. Finally, leather no longer needs to be time-consumingly clamped for processing. Simply place the sheet on the laser table and engrave or cut the desired pattern.

For laser engraving on leather, a CO2 laser is the best machine you can choose. It provides optimal results and can quickly engrave any type of leather effortlessly with its incredible power.

As leather is so abundant and versatile, the possibilities you can cut/engrave are virtually limitless! Below is a list of some of the beautiful leather creations you can make with a laser:

Bookmarks – Bracelets – Briefcases and laptop bags – Coasters – Guitar strap – Hat patch – Headband – Journals – Keychains – Necklaces – Home decorations – Pet collar – Photo – Wallets and purses – Shoe – Sports memorabilia – Passport cover