Why Choose Glass Laser Engraving?

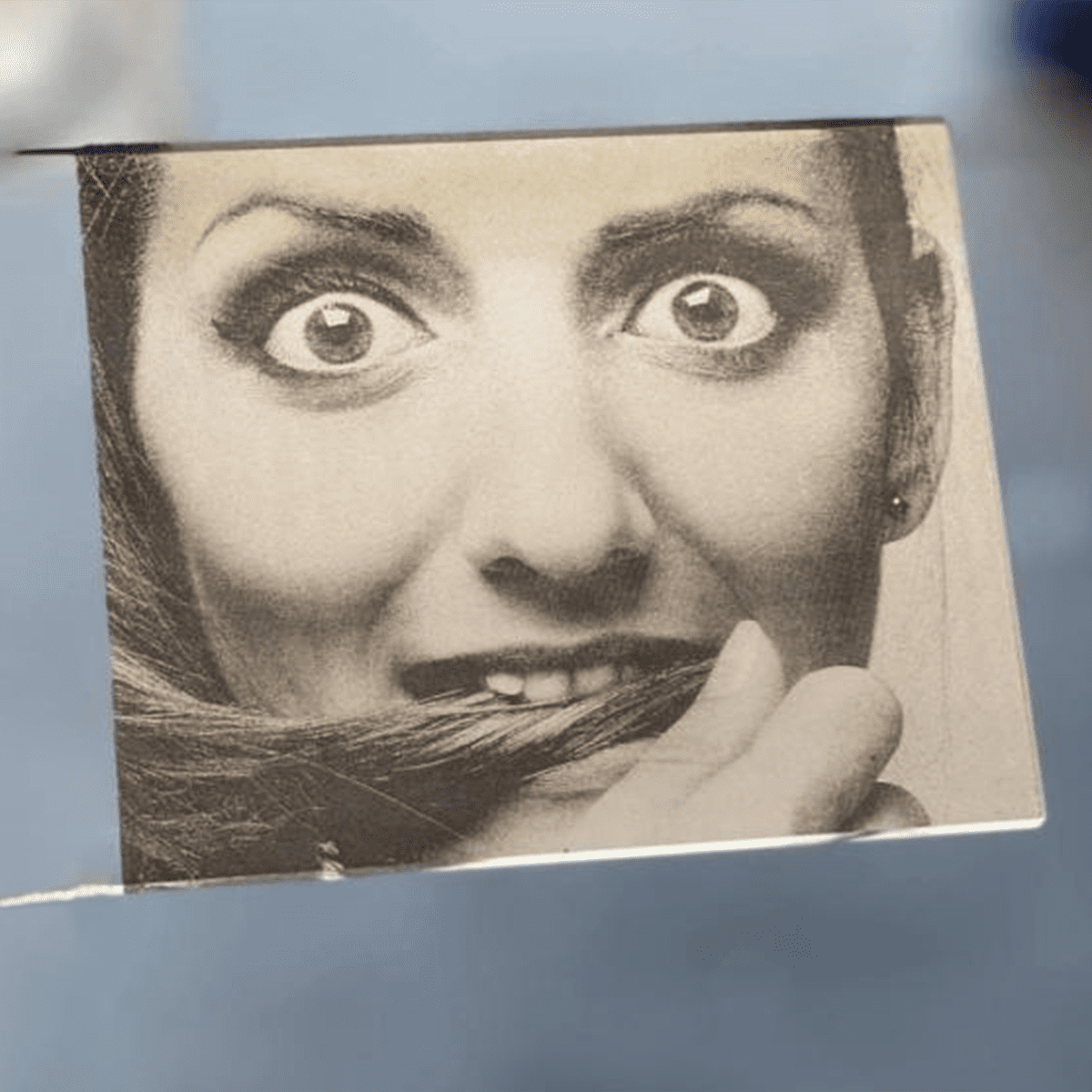

Glass can be marked in various ways: printing, screen printing, sandblasting, manual engraving machines, glass laser engraving, or engraving with rotary equipment. With a laser engraver, you can easily, precisely, and impressively perform glass laser engraving on glass, mirrors, or crystal. Unlike mechanical engraving, the laser processing process itself does not create pressure in the glass, greatly reducing the risk of breakage of the fragile round glass. Whether you are laser engraving photos, texts, or logos on glass, you will achieve stunning matte finishes, finest contours, or details.

There are several compelling reasons to choose glass laser engraving:

1.Precision: Laser engraving machines offer unparalleled precision and detail. Even the finest images and texts can be engraved extremely accurately, allowing you to create highly detailed patterns.

2.Speed: Laser engraving is a faster process, allowing you to finish glass products in the shortest time.

3.Durability: Designs engraved with a laser are stored in digital files, ensuring consistent quality and the ability for easy reproduction.

4.Non-contact processing: During laser engraving, the glass is not touched, reducing the risk of damage from the engraving process significantly.

5.Versatility: Laser engraving and etching are versatile and suitable for a variety of glass products and types.

6.Excellent end result: Laser engravings provide an impressive matte finish and fine contours, enhancing the quality and appeal of your glass products.

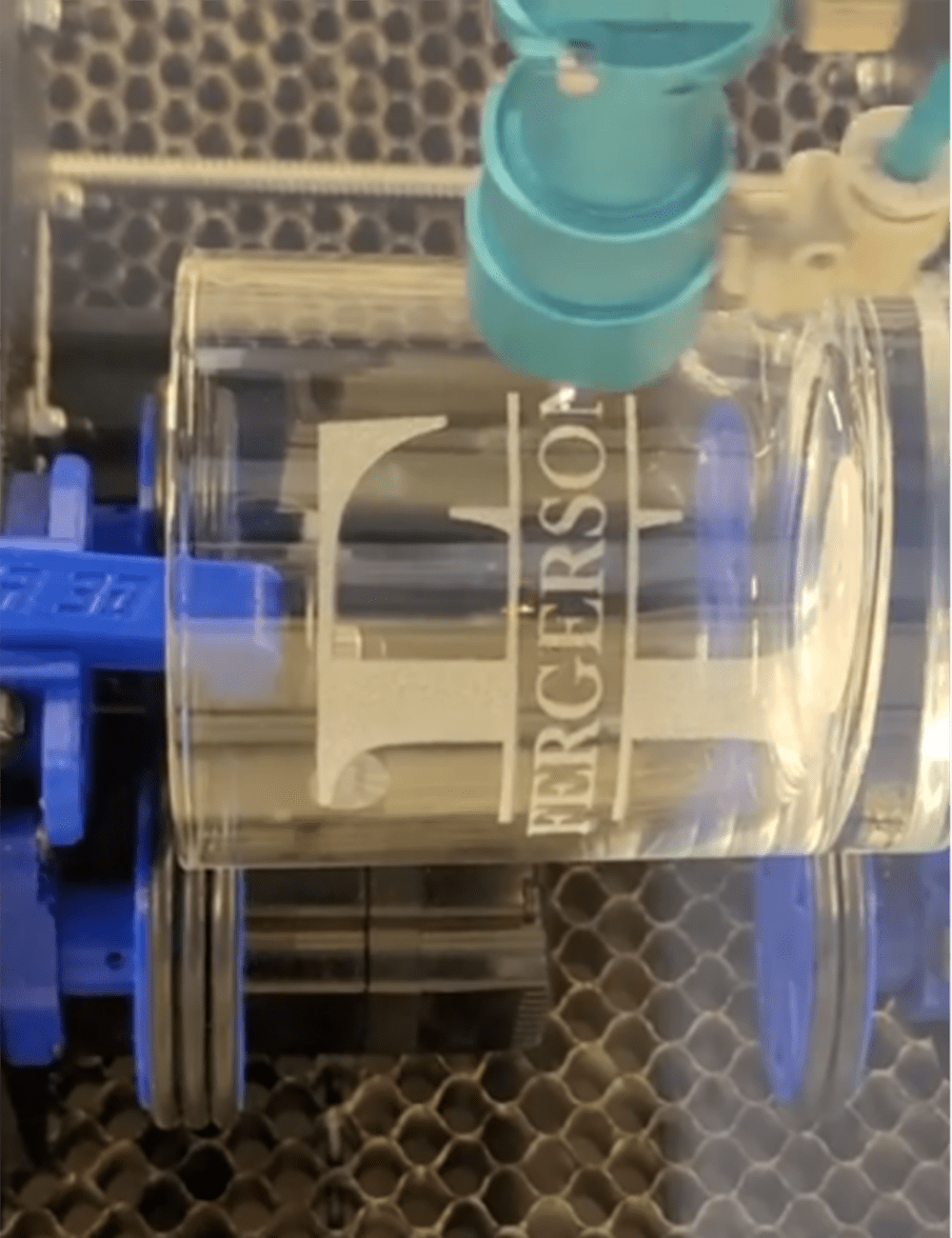

How can glass laser engraving be performed on curved surfaces?

Engravings are usually easiest on flat surfaces, as they require a certain focal length and fixed distance between the lens and the material surface. This limits the application to hollow glass objects such as beer and wine glasses as well as float glass. However, for engraving glass objects with curved surfaces such as bottles, vases, and wine glasses, there are solutions. The use of a rotary attachment, connected to the laser machine, allows glass objects to be rotated during engraving, thus creating the desired pattern. However, extremely complex angles or curvatures may still pose a challenge.

Which glass is suitable for glass laser engraving?

The best types of glass for laser engraving are those with a low metal content, preferably soda glass. Inexpensive glass products usually achieve excellent results. In general, materials with very low metal content are best, as the laser cannot engrave areas where metal particles are present in the glass. However, glass with a high lead content, such as crystal glass, is less suitable for laser engraving, as lead tends to expand at different rates and cause cracks in the glass.

What are the advantages of glass laser engraving?

Laser engraving and etching offer several advantages over other methods such as sandblasting or mechanical engraving:

Precision and speed: Laser engravings are extremely precise and fast. Even the finest details can be engraved with high precision.

Robust and consistent: Designs are stored as files, allowing them to be reproduced in consistent quality.

Non-contact marking: This means that the glass does not need to be clamped, minimizing the risk of breakage.

Economical and efficient: Laser engravings require fewer tools compared to other methods, making them more cost-effective.

Versatile and easy to apply: Lasers are more tolerant of errors compared to mechanical engraving or sandblasting.

Less cleaning effort: Compared to processes like sandblasting, laser engravings require less or no cleaning.

Tips and tricks for glass engraving and laser marking.

How to avoid glass breakage?

When the laser beam comes into contact with the glass surface, the glass heats up, causing the glass particles to expand. If the glass cannot cool down sufficiently, the depressions created will become larger, resulting in poor engraving results. This is particularly problematic with high-quality glass, as glass does not have a fixed melting point. To avoid glass breakage, you need to distribute or reduce the heat evenly. Here are some methods:

Use laser masking tape: This protects the glass from excessive heat and reduces the risk of breakage.

Moist towels: Lay moist towels flat on the glass surface to be engraved. Ensure there are no air bubbles, as these can cause issues during engraving.

Moist paper: Moist paper can be placed on the glass surface to absorb and distribute the heat evenly.

Dish soap: Applying dish soap to the surface to be engraved can dissipate the heat and prevent breakage.

Note: The laser masking tape should cover the contact area of the laser, as this is where it is most effective. The inside of the glass has no effect.

How can the unity of glass laser engraving be improved?

After cleaning the glasswork post-engraving, you can add color to enhance the overall appearance. Washable paints or colored inks achieve good results. Alternatively, you can use special glass markers, being cautious when applying on glass as glass is more delicate than other materials.

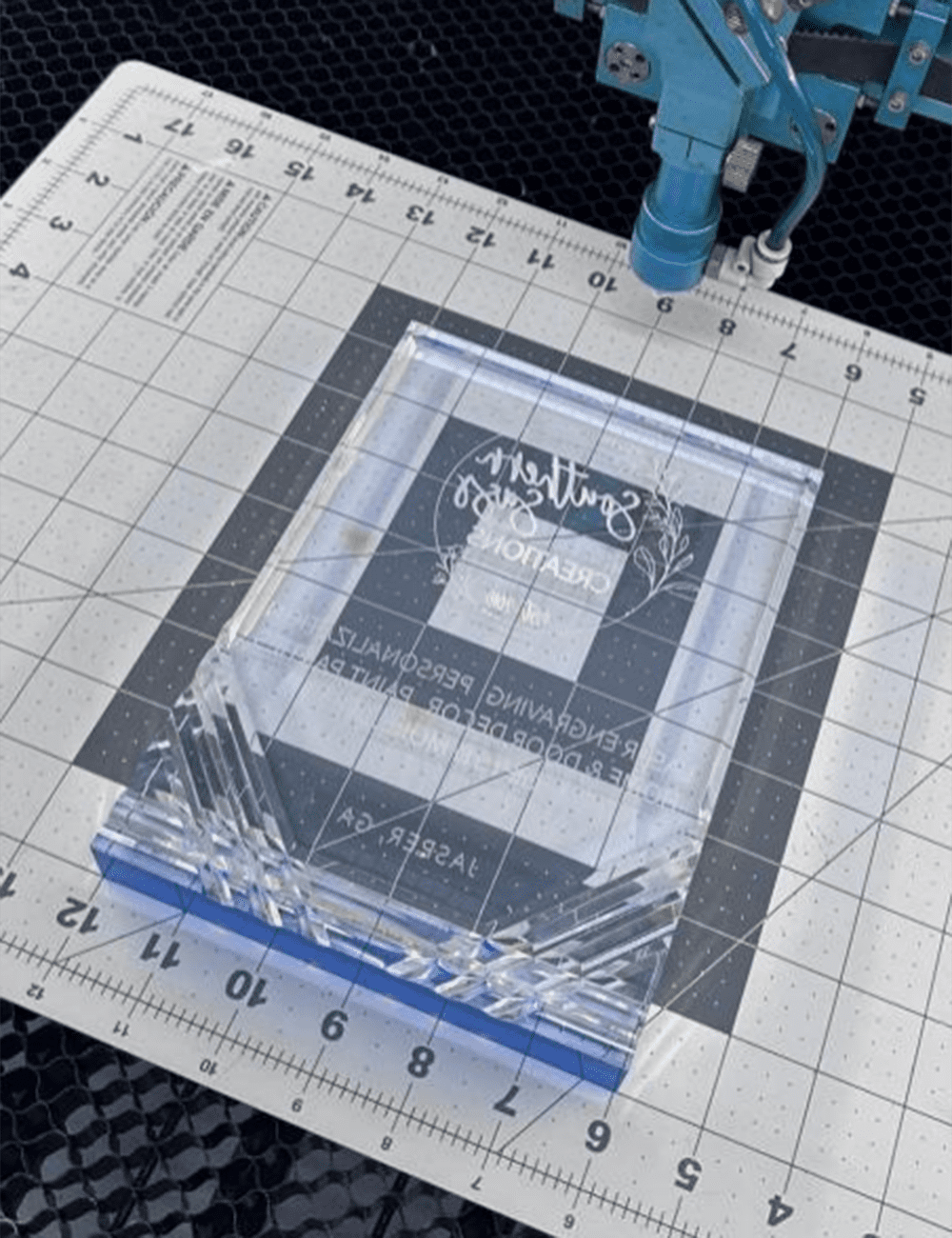

Which model is best suited for my glass engraving project?

Regardless of the model in the NOVA series, its extremely high processing speed and precise laser control achieve excellent results in glass engraving. However, NOVA 51 and NOVA 63 offer distinct advantages in engraving flat glass plates due to their higher laser power and an extended working platform, including a pass-through door.

Decide based on the priorities of your project which model best suits your needs.

For further details, please click here: