Applications of Laser Engraving on Stone

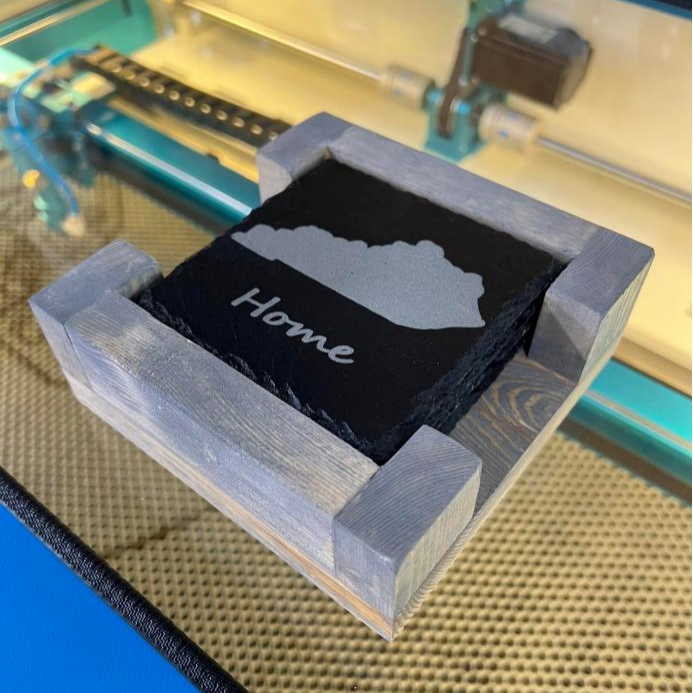

A laser engraving machine is the best choice for stonemasonry work. Laser-engraved gravestones or monuments are typically expensive. Due to their durability, most gravestones are made of granite, but sandstone, slate, and natural stone flags have also been used, creating a unique contrast effect in laser engraving.

Engraving text and photos on various stones such as granite or marble is highly popular in emerging markets such as jewelry, interior design, crafts, events, gifts, and signage. Another application of stone engraving is wall or floor tiles.

Laser etching is primarily applied to slate, tiles, and bricks. These materials turn white when burned by the laser, creating a natural contrast. For other materials such as marble, granite, basalt, lava stone, natural stone, pebbles, ceramics, porcelain, and black granite, color or dye is required after engraving to achieve a good color effect.

Engraving photos on minerals can be somewhat complicated as it depends on the condition of the surface. For best engraving results, the stone should have an optimal flat surface to prevent distortion in the final result.

We recommend using very dark black marble (or very light white marble) for better contrast. Polished slabs or stones with very smooth surfaces provide the best laser engraving effect. The common practice is to set the photo resolution to a maximum of 300 DPI to achieve good results. This resolution can be increased if the surface is uniform and smooth.

Some stones produce or yield very poor results when carved. However, by subsequently filling the carving with acrylic paint (or a similar type of paint), you can still achieve highly contrasted results. To do this, cover the surface to be carved with tape, then carve the desired pattern. Next, take the acrylic paint and brush and dab the carved area. Once the paint has thoroughly dried, remove the tape and wash off any fine adhesive residues with water. The smoother or finer the stone surface, the better the effect after filling. Porous or rough surfaces may cause the edges of the artwork to appear worn and dull.

The advantages of laser engraving on stone compared to other techniques:

1.No wear and tear

The first advantage of laser engraving is that there is no wear and tear. Engraving with drills and chisels is very difficult as it’s hard to control how much force is exerted, leading to cracks or other wear on the object. Even when using a CNC drilling machine, there is still the possibility of wear due to physical contact. With stone engraving using a laser engraving machine, there is no physical contact between the machine and the object. This prevents wear and tear on the object, allowing for perfect ease and good results every time.

2.Fast production speed

Laser engraving machines are very fast, and when using a powerful machine, the speed can exceed 100 mm/s or higher, depending on the type of machine and laser power. Engraving can be done in one pass without the need for pre or post-processing.

3.Incredible precision

The precision of laser engraving machines is amazing. With their sturdy construction, positioning sensors, and precise motors, engraving is carried out as accurately as possible. With some laser engraving machines, accuracy can be up to 0.0004 inches, meaning you won’t see any errors or defects. Even when performing vector engraving, repositioning accuracy can be up to 0.0007 inches. This ensures that the laser returns to the same point when needed, eliminating any obvious errors.

4.Fully implement complex designs

With CNC drills and conventional methods, you cannot engrave very complex designs. Due to physical contact, there may be damage to the object with too small or complex designs. However, with a laser engraving machine, you can engrave any desired design, no matter how complex or small it is. The laser engraving machine delivers perfect results. The laser spot of the machine is typically less than 0.10 x 0.10 mm. You can also engrave fine details with the machine.

5.Waste-free process

There is almost no or very little waste in stone laser engraving. In most cases, the laser will mark the stone but not remove any material. But even if some material is removed, it is very minimal. There is also no waste during the process. You will not be covered in dust and particles from the object.