Laserschneider haben eine breite Palette von Anwendungen und einzigartige Vorteile bei der

Laser cutters have a wide range of applications and unique advantages in processing PE foam materials. PE foam is a lightweight, flexible and durable material that is commonly used in packaging, protection and filling applications. Laser cutters utilize high-energy laser beams to cut and engrave PE foam, opening up new possibilities for processing these materials.

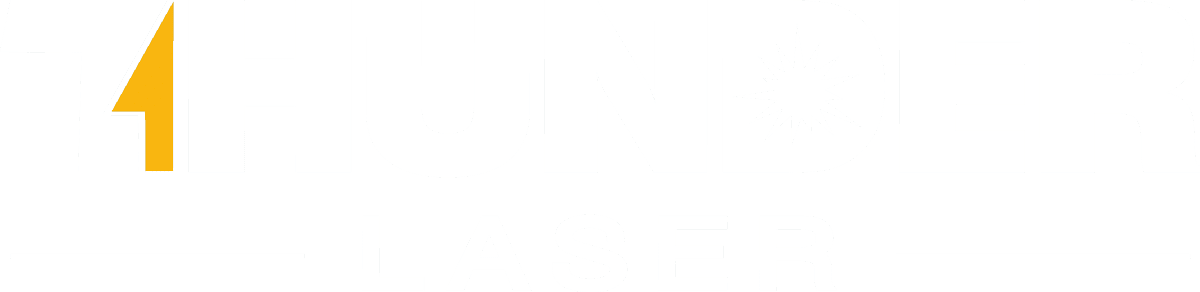

Laser cutters enable high-precision cutting and engraving. Due to the softness and fragility of polyethylene foam, traditional cutting methods can lead to edge damage or uneven cutting. Laser cutters can achieve precise cutting of PE foam by adjusting the energy density and focus position, ensuring smooth edges and accurate shapes.

Laser cutters are easy to operate, efficient and flexible, allowing for quick adjustments to cutting paths and parameters according to design requirements. Without the need for physical molds, different shapes and sizes can be cut without time and cost spent on mold production. In mass production, laser cutters can quickly handle cutting tasks of varying shapes and sizes, thereby increasing production efficiency and capacity.

In the area of product packaging, laser cutters offer particular advantages when applied to polyethylene foam. On one hand, laser cutters can quickly and precisely cut customized packaging inserts or protective cushions to match the size and shape of the product, providing adequate protection during transportation and storage. Customized packaging inserts reduce gaps between the product and packaging, preventing potential damage from vibrations during transit.

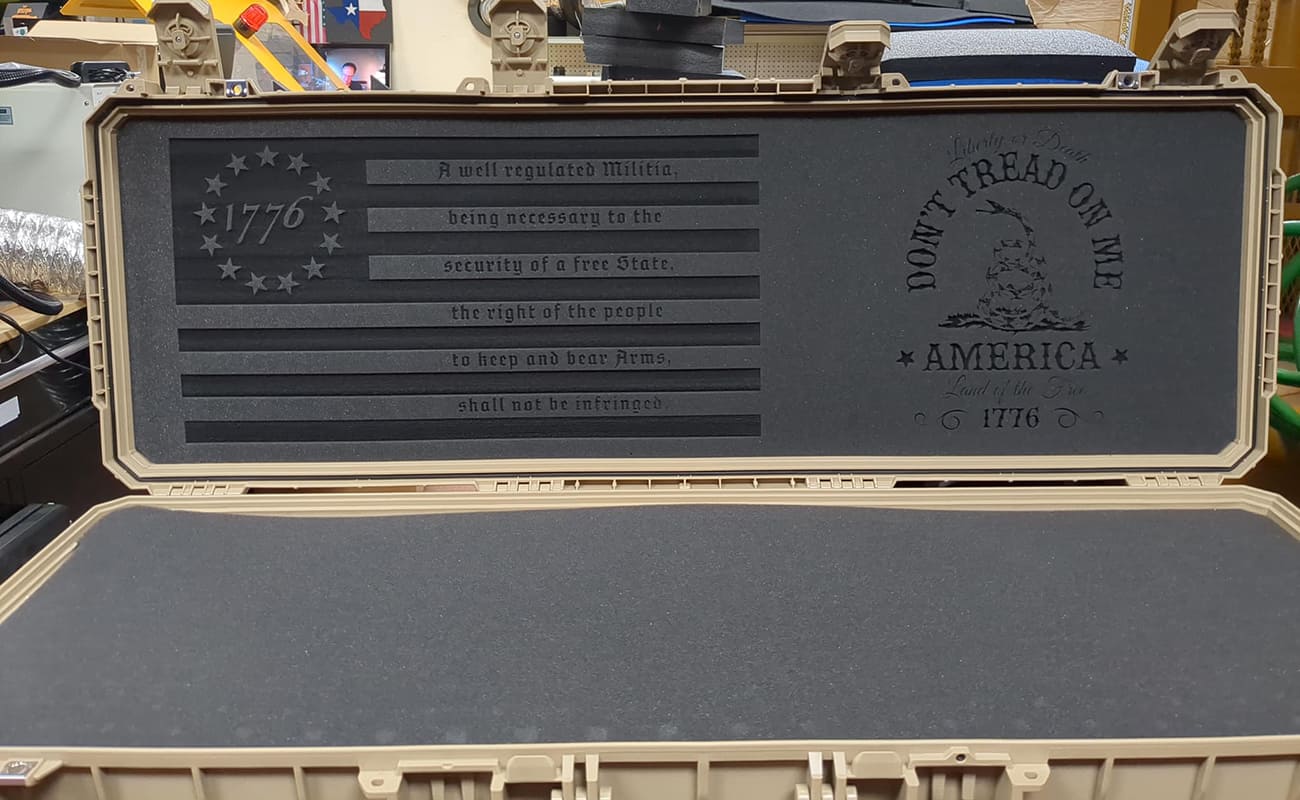

Laser engravers can also directly engrave onto PE foam by printing product labels, brand logos or patterns onto the packaging inserts. This lends a personal touch and uniqueness to the product packaging, enhancing brand image and advertising effectiveness. Furthermore, laser-engraved markings and patterns are clear and durable, unaffected by wear or fading, ensuring lasting visibility.

Moreover, the pollution-free and contactless operating mode makes laser cutters an environmentally friendly and safe processing option. Laser cutting generates neither dust nor debris, avoiding environmental pollution for the surroundings and operators. The contactless laser cutting process exposes the material to neither pressure nor deformation, preserving the original performance and quality of the PE foam.

With the continuous advancement of laser technology, laser cutters are expected to play an increasingly important role in processing PE foam materials.